And The Good News? Stoll Machines Last Decades.

So, What Does The Hitchhiker’s Guide to the Galaxy Have in Common With Sports Bras, Aerospace Compos

Well… everything, apparently.

When the news broke that STOLL’s Reutlingen site was closing, many of us in the knitting universe felt like Arthur Dent — standing barefoot in our bathrobes, watching the planet vaporize for an intergalactic bypass. But if we’ve learned anything from both the Hitchhiker’s Guide and the textile industry, it’s that endings are usually the messy beginnings of something far more interesting.

At Fabdesigns, we realized our world diverged from STOLL’s long ago — not of our choosing --- but probably at just the right moment to survive the impact. Like hitchhikers with a towel and a pocket full of yarn samples, and 14 patents, we’ve built our own spaceship: one powered by innovation, collaboration, and the conviction that the answer to sustainable manufacturing isn’t 42 — it’s partnership, precision, and persistence.,Along the way, we’ve gathered quite the cast of characters: IP guardians, polymer alchemists, carbon fiber spinners, feed system experts, feral sewing experts, waste management experts, and creative adventurers in auxetics that are as crazy as we are about exploring the unknown in interactive fabrics. (You all know who you are.)

We picked up fiber experts, the finest material supply companies, factories, laminators, finishers and hardware jewelers, artisans that knit, weave, sculpt, and assemble many sought after types of products across several continents, all making exceptional quality products for forward thinking designers, brands, and start ups interested in sustainable business.

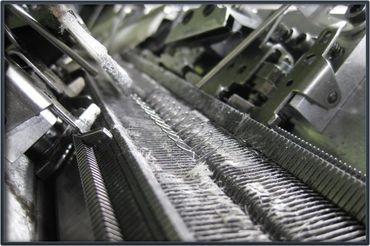

Together, we’ve charted a new course through the textile galaxy of materials and processes - stunning brands with things no one has ever done before — while Fabdesigns continued connecting and modifying legacy machinery from STOLL, Shima, Cixing, and Steiger to future-forward technologies and materials, that can still make magic.

And the good news? Stoll machines last decades. The real power was never in the logo — it was in the people who learned how to make them sing. There are a lot of people who make beautiful things on Stoll machines in the knitting galaxy and many more who want to learn. In our experience Stoll machines last at least 30 years, with good care, and there is a lot of innovation still to come. Much of it can be translated to other machine technologies.

So, grab your towel and your favorite knit swatch. We’re headed into the next chapter of engineered materials, smarter systems, and knitted solutions that could change the world.

grafitti on a wall wat now?

Our Innovative Engineering Solutions in Action

Yes, our space ship used to be predominantly Stoll based and the closure of Stoll machine production is a bit of a challenge if people are starting out. We know what we’re doing. Like many others, we could buy used Stolls and be just fine for the next thirty or more years. The main issue is scaling production for other people, brands, and start ups and new students learning. Finding suitable and quality machines, scattered across the globe, inspecting them individually, and putting a facotry together. Who is going to do that thankless work?

The truth is that the value of Stoll machinery plummeted on their first announcment, because new customers – even for used machines – can’t get adequate service or training. We and others can fill some of that, but this is standardized training and service that Stoll built into their machine sales pricing, which clients recieved at no charge under warranty. The machines are work horses and each machine will last a few decades with proper care and maintanance, should there not be a buyer for Stoll. One question that begs to be asked is, what is so broken at Stoll that it could not be fixed in place at Karl Mayer?

At Fabdesigns, we’ve never been afraid to evolve, even through adversity. In our 3D knitting galxay, it is change or perish. Over the past decade, we’ve been quietly restructuring — refining our patents, strengthening partnerships, and building a global network of some of the best yarn suppliers, knit manufacturers, and technical innovators in the world. What may have looked like silence was actually focus. We realized that innovation works best when we stay true to what we do best — and collaborate with others who are just as passionate and precise. We are a small business, independent and self funded and we were able to build and adapt through some very rough times, including the Woolsey Fire, the pandemic, a divorce, and the Los Angeles Fires this past year. Why is this ability to pivot and evolve so illusive at Karl May Stoll?

The heart of our own engineering and innovation is building to needs - not ours but of the industry and customers; envisioning and anticipating what leaps will come next.

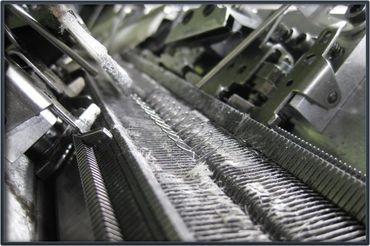

Not finding what we and our clients needed on the market, we built our own technologies. We developed advanced knitting technology for not only Stoll machinery but to deliberately include other brands of textile equipment as well. Change a machine and change it's capabilities. Our systems are modular, removable and do not damage the original machine.

Our patents are:

- Platform technologies (enable entire categories)

- Multi-industry (footwear, medical, aerospace, automotive, wearables, IoT)

We focused on optimizing how to use the current and legacy equipment and how to build the future with the machinery a factory already has, should something like what just happened to Stoll occur. We saw it coming in slow motion, and built an ecosytem of technology over 14 patents and counting that includes adding new machine parts, warp inserts, and feed systems to embed wires, create 3D composites in any shape we want, and build complex structures and circuits in a very small amount of space. We built systems to create multi-layered composites and artificial ligaments that have never existed before and next generation footwear with functions that have never been possible before - all customizable.

We built these technologies to span not just Stoll machinery, but many other flat knitting brands and other types of textile machines and applications.

Our 6 Patents Technologies - Reframed

We have 14 patents in 6 individual platforms, each one:

- Changes how things are made (manufacturing disruption)

- Changes how things interact with IoT (connectivity revolution)

- Applies across multiple industries (footwear, medical, aerospace, automotive, wearables)

This isn't a patent portfolio. This is an INDUSTRIAL REVOLUTION TOOLKIT.

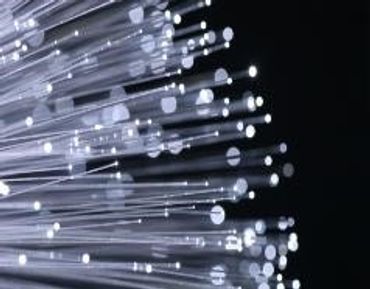

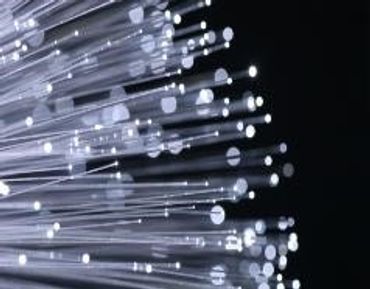

To build e-textiles was a challenge of the past. Today, we build circuits which machines were not capable of making before. With just one part of our technology, produced and distributed exclusively by Memminger IRO, up to 22 wires or functional strands can be embedded in every knitted panel, consistently and without packaging twist adding resistance.

We've patented technologies that span industries from apparel to aerospace. Our confidential client partnerships focus on finding the right fit of companies that want to exploit this technology in licensing, and focused toward acquisition and full transfer of our proprietary patents and technology. Our projects are curated to ensure alignment and avoid conflicts of interest. Contact us for a prospectus.

The 145-Page Prospectus :

We haven't just documented our patents.

We documented 6 PLATFORMS that change:

- How wearables are manufactured (IoT connectivity)

- How medical devices are made (artificial ligaments, sensors)

- How footwear is constructed (performance zones, embedded tech)

- How aerospace materials work (composites, de-icing, sensors)

- How automotive interiors function (heated, sensing, connected)

- How textiles interact with IoT (the unifying platform)

Each platform enables billions in new products.

Join the Journey

We’re opening our sourcing and client network to designers, technicians, factories, and brands who want to collaborate on the next generation of textile innovation. Whether you’re looking for materials help, build a prototype, or launch a sustainable product line, we’d love to hear from you.

Because while the universe may be vast and unpredictable — innovation is always better when we hitchhike together.

We're Engineering Solutions for a Better Tomorrow

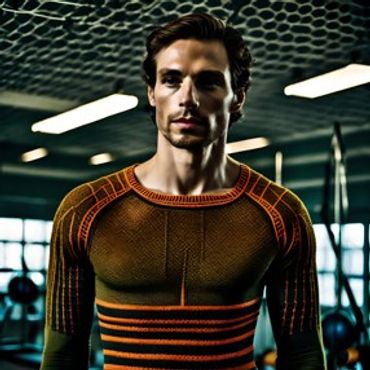

Smart & E-Textiles with Flexible Electronics

Imagine if your pullover could monitor your posture, your sleeve could control your VR headset, or your running tights could track recovery in real time. Our patented smart textile structures with embedded circuits, fiber optics and sensors integrate flex electronics seamlessly into performance fabrics — built for wellness, gaming, defense, and immersive environments.

Creating Circuits in 3D Composites

We’re embedding connectivity into the material itself. Using conductive yarns and embedded circuitry, we’re turning textiles into self-sensing, energy-dispersing structures that integrate directly into composites and wearables. By conductive we mean transmission: heat, data, light, energy, and more.

Why we built and patented this technology:

1. Big Tech Applications & the IOT

- Virtual Reality (VR):

- Video Gaming:

- SportsTraining:

- Medical Rehabilitation:

- Security

- Health & Wellness:

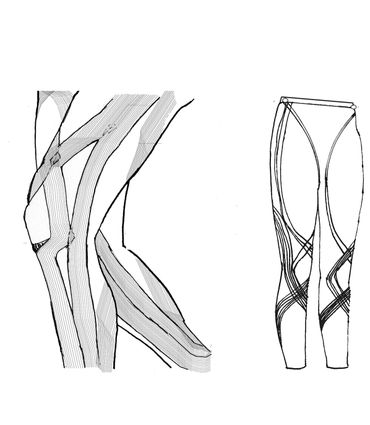

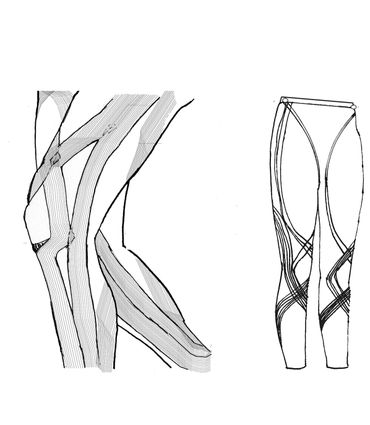

Artificial Ligaments Embedded in Activewear and Composites

Who says softgoods can’t be strong? We’ve engineered biomimetic knit structures that behave like ligaments — flexible, supportive, and astonishingly strong. From rehabilitation wear to composite reinforcement, this is where biology meets engineering.

5-Dimensional Technical Knit Structures

If 3D knitting changed the game, 5D is changing the universe. Our patented systems combine topology, density, texture, compression, and memory — creating responsive, intelligent textiles that move, flex, and adapt in real time.

Why we built and patented this technolgy:

Anatomical Enhancement Applications:

- Yoga & Theraputics

- Wellness / sports rehab

- Aging Athletes cycling, running, ski / snowboard

- Protective & Medical Devices

- Anti-fatigue & Posture Garments w/ Ligamental Support

- Advanced Military Apparel

- Reinforced Compression Wear

- Enhanced Performance Footwear

- Smart Wearables

- VR & AR & Audio/ Gimble Wearables

- Lightweight Reinforced Composites

- Reinforced Structural Panels

After-Processes for Technical Textiles

RF Welding and Technical Tapes

The future is sealed tight. Our RF-weldable composites and technical tapes create watertight, air-tight, and performance-driven joins that outlast traditional stitching.Finishing isn’t an afterthought — it’s the alchemy that unlocks performance. We build from the polymer or fiber forward. We use Bemis, which is the most reliable tape that we've found for bonding knit technology. Our proprietary after-processes include thermal fusion, polymerization, pocket and channel sealing, Active Seaming, Sensor connection, RF and EF shieding, hook and loop landing pads, fiber optics, live hinges, mechanical refinement, custom prepreg finishng, origami layered structures, and coatings that elevate durability, comfort, and function without waste.— built for medical, aeospace, gaming, defense, footwear, aerospace and auto composites, home, and immersive environments.

Adhesives and Seams for Knit Structures

Traditional adhesives weren’t made for knits — so we re-engineered them. Our low-temp, high-flex bonding systems maintain strenght, where as Active Seams stretch, recover, and provide durability without compromising comfort or sustainability.

RF Welding and Tapes

The future is sealed tight. Our RF-weldable composites and technical tapes from Bemis create watertight, air-tight, and performance-driven joins that outlast traditional stitching.

Why we built and patented this technology:

1. Big Tech Applications & the IOT

- Connectivity

- Luggage and Travel Bags

- Upholstery and Furniture

- Advanced Footwear

- SportsTraining:

- Medical Rehabilitation:

- Security

- Modularity, Flex and Strength in Aerospace

- LIght Weight Strength in Automotive & Marine

- Reinforced Drone Components

- Energy Harvesting Applications

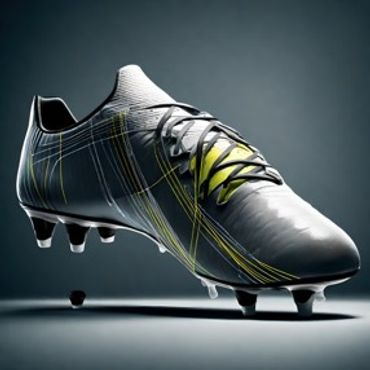

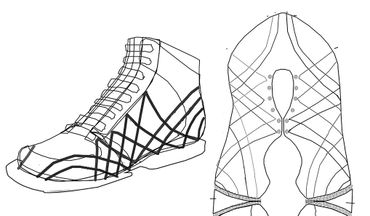

Completely Seamless Footwear

No cuts. No glue. No seams. Just pure, programmed perfection. We pioneered fully formed footwear long before it was fashionable — and our next-gen methods combine 3D shaping, structural zoning, and sustainability in ways that even Arthur Dent would approve of (if he ever found shoes that fit). We have multiple patents in this technology, including isolated composite (carbon fiber) structures that are 3D built with precision and customizable. This is where anatomical fit meets engineering.

Why we built and patented this technolgy:

Anatomical Enhancement Applications:

- Cycling

- Futbol

- Basketball

- Hockey

- F1 and Indy race car footwear

- Performance & sports rehab

- Aging Athletes

- Protective & Medical Devices

- ·Advanced Military Gear

- Reinforced Compression Wear

- Enhanced Performance Footwear

- Lightweight Reinforced Footwear

After-Processes for Technical Textiles

Why choose between rigid and flexible when you can have both? Our isolated composite zones and embedded re-inforcement bring aerospace logic to composites, apparel, footwear, and more -- merging stiffness, flex, and protection in a single integrated form.layered structures, and abrasion/impact zones that elevate durability, comfort, and function without waste.— built for medical, aeospace, gaming, defense, footwear, aerospace and auto composites, home, and immersive environments.

Why we built and patented this technology:

1. Big Tech Applications & the IOT

- Connectivity: Heat, Energy, Light, Data

- Luggage and Travel Bags

- Upholstery and Furniture

- Advanced Footwear

- SportsTraining:

- Medical Rehabilitation:

- Security

- Modularity, Flex and Strength in Aerospace

- LIght Weight Multi-Performance in Automotive & Marine

- Reinforced Drone Components

- Energy Harvesting Applications

3D Knitted Biomedical Solutions

Textiles that heal, support, and move with the body. From vascular scaffolds to orthopedic supports, we’re translating decades of knit precision into biomedical-grade structuresthat could redefine recovery and performance. structures that are 3D built with precision and customizable. This is where anatomical fit meets engineering.

Protective Structures: Gloves, Footwear & Medical Bracing

Protection doesn’t have to mean bulk. Our advanced patterns create multi-density knitted shields for hands, feet, and joints — balancing dexterity, breathability, and impact resistance through fiber and form alone.

Why we built and patented this technolgy:

Anatomical Enhancement Applications:

- Cycling Pants

- Futbol Gear & Footwear

- Basketball Anti-Rollover

- Hockey Armor

- Aging Athletes

- Protective & Medical Devices

- ·Advanced Military Gear

- Reinforced Compression Wear

- Enhanced Performance Joint Pads

- Lightweight Reinforced Footwea

Our Innovative Engineering Solutions in Action

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.